DRYERS, LOADERS, BLENDERS

and MATERIAL MANAGERMENT SYSTEMS

Visit the Thoreson McCosh web site:

www.ThoresonMcCosh.com

Thoreson McCosh

1885 Thunderbird

Troy, Michigan 48084

Phone: 248-362-0960

Thoreson-McCosh is a manufacturer of desiccant dryers (dehumidifying) and auxiliary equipment for the plastics industry.

They manufacture standard or custom desiccant dryers, loaders, blenders and material handling systems to meet your specific needs.

- Hopper Dryers

- Thermoplastic Resin Dryers

- Compressed Air Dryers

- Hot Air Dryers

- Loading Systems

- Hopper Loaders

- Machine Loaders

- Vacuum Loaders

- Compressed Air Loaders

- Venturi Loaders

- Vacuum Transfer Systems

- Material Handling Systems

- Pull Push Rail Car Unloader

- Silo (Storage Silos)

- In-Plant Surge Bins

- Resin Dry Bins

- Resin Blenders

- Color Blenders

- Gravimetric Blenders

- Color Additive Feed Units

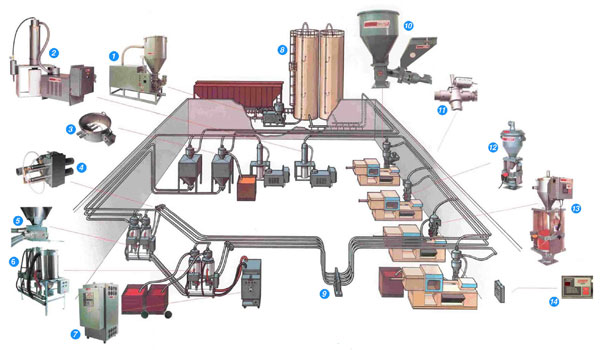

- 1Pull/Pull Conveying Durable Pull/Push railcar unloaders offer the advantage of vacuum and pressurized material conveying in one unit. Offer superb quality, reliability and engineering, these units utilize a single TEFC ball bearing motor, provide an automatic purging sequencer to prevent material slugging and have a rotary valve for metering material flow. Available in sizes 15 HP - 50 HP and capacities 7,500 lb/hr - 25,000 lb/hr.

- 2Positive Displacement Pumps Regenerative Type Vac Pump and Two Types of Central Filters for reliable material conveying and filtration. Pumps are available in either regenerative or positive displacement type units with a fully enclosed pump and motor for durable component protection and noise reduction.

- 3Virgin/Regrind Proportioning Valve User-friendly ratio proportioning valve turns any receiver into a Virgin/Regrind Loader. Valves are easily retrofitted to any existing system. Once installed, simply adjust the control knob to the desired setting for consistent material proportioning. These specially designed valves minimize material layering by pulsating the loading sequence between the two materials.

- 4Purging Valves For clean and simple material changes. Designed for either dry or ambient air conveying, purging valves keep material lines free of pellets, eliminating possible material contamination and moisture re-absorption.

- 5Dry Air Conveying Conveying systems safeguard against material moisture contamination. Systems can be customized and provide efficient and economical conveying.

- 6Central Drying / Multiple Drying Hoppers Maximize drying efficiency, versatility and ease of operation. Design for maximum air dispersion to ensure thorough material drying. Multiple hopper arrangements enable drying a wide variety of materials and/or colorants simultaneously. Pre-heaters are also available for individual hopper temperature control. An insulated manifold with manual shutoff valves allows for individual air flow control to each hopper.

- 7Desiccant Dryers Wide range of high quality, high efficiency dryers covered under 5/30 warranty (5 years on bed seals and 30 months on entire dryer).

- 8Silos Wide range of FDA approved silos to suit your specific needs,, including corrugated, galvanized, aluminum, steel, painted, bolted or welded. Truck delivery and one day installation provided.

- 9Material Manifold Customized material manifolds with quick disconnects offer clean, simple material selection and changeover to suit your central vacuum system.

- 10Precision Additive Feed Units Featuring titled design to eliminate potential of excess colorant from being vibrated into the melt system. Optional controls to track molding machine screw speed and assure quick, easy color changes. Variety of additive feed units and controller types for maximum dependability.

- 11T-Valves/Compressed Air Sequencing Well-managed loading systems begin and end with compressed air sequencing valves that supply vacuum to every loading station on line. Installing these units directly on the vacuum line as opposed to on the receiver itself allows for safe operating conditions, reduced receiver weight, and eliminates the risk of valve damage during receiver cleaning.

- 12Minimum Inventory Receivers Comprehensive one and two shot material management designed to decrease material changeover time and eliminate hygroscopic material from moisture re-absorption. Versatile units available with adjustable proximity switches and Tech 3 controls for material level management. Simply pre-set the load size to match your machine's throughput.

- 13Tech 12 Single Station Controls For molding operations that call for a higher degree of material management. Microprocessor driven "Tech 2" units feature user-friendly access. Ergonomically-designed units feature simple load time set up and a NEMA-12 enclosure for easy maintenance and security against unwanted tampering. Fully expandable.

- 14Protek-A/B Loading System Controls Standard Features:

- Vacuum readout through vacuum fluorescent display

- Purging valve control through vacuum fluorescent display

- Capable as standard of controlling two vacuum pumps

- Status of station loading point displayed

- No load alarm - material runs out - alarm is displayed

- High amp alarm - signals an alarm if motor overload is tripped

- Dirty filter alarm on central filter

- 24 history of alarms

Call Day Plastics Machinery for more information on Thoreson McCosh Products

508-655-1721

or Send Email to our office Now!

Day Plastics Machinery, Inc. 25 Grey Wolf Drive Franklin, MA 02038

Phone: 508-520-1207 ©2020 Day Plastics Machinery, Inc.On the Dream